Galvanized Steel Bolt Connected Water Tank

Technical Specification

1. Design

1.1 Material

The panel is made of Q235 steel by hydraulic punching machine;

The size of the panel is :1220*1220mm, 1000*1000mm,1000*500mm, 500*500mm;

The thickness of the panel mainly includes: 5mm, 4.5mm, 3mm, 2.5mm, 2mm, 1.5mm. It is different according to the tank dimension.

1.2 Flanges

The sectional panels shall be pressed to double flanges at the angles of 45 degree and 90 degree to the face of the plate on four sides.

1.3 Reinforcement Method

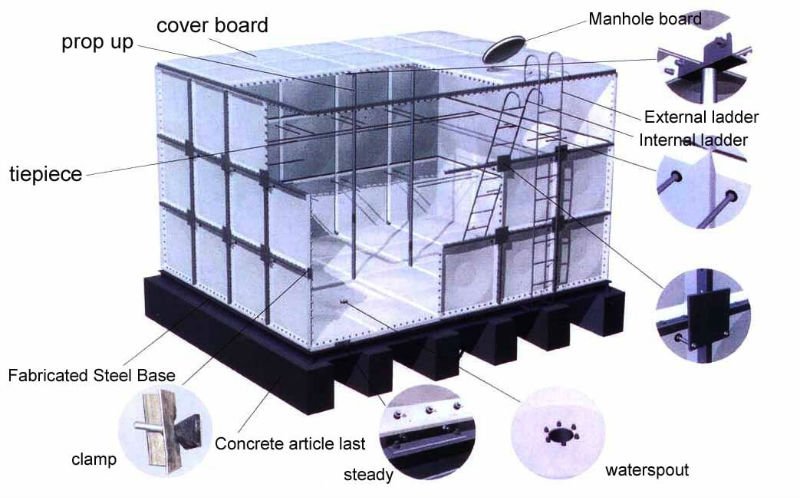

All tanks are internally braced with angle stays to endure the rigidity of the tank when filled with the water. The Top panel is supported by top panel support, which shall be made of hot-dipped galvanized material.

2. Accessories

2.1 Bolt. nut & washers

hot-dipped galvanized material.

2.2 Sealing material

Non-toxic P.V.C foam tape shall be used in between the joints.

2.3 Covers

The tank cover shall be constructed from 1.4mm to 3.0mm of thickness hot-dipped galvanized material according to the requirement.

2.4 Ladders and Level Indicator

Internal & external ladder shall be made of hot-dipped galvanized material.

Application:

This water tank is widely used in storage and regulation of living water supply & construction water supply, and temporary water storage tanks for expansion of the heating system, condensate tank and construction, geological survey, industry, National defense project etc.

Various industries, civil water supply, HVAC, firefighting, food, beverage, vintage, water treatment, medicine, petroleum, chemical and so on. Taking flexible, reasonable plate design, suitable for all sizes combined water tank.

Suitable for living water with PH value:6.5-8.5, using life:≥20 years

Installation Instructions:

1.Water tank foundation requires the geometry dimensions of concrete foundation should follow relative stipulations of GB02S101 to be made. The height tolerance of the concrete foundation flat is <5mm;

2.Water Tank Installation:

Construction and Acceptance: professional welders weld by argon arc welding at site;

With standard power in construction field;

Around the water tank , there are intervals ≥500mm for inspection;

visual inspection: no rust, no pollution; cabinet without obvious deformation, weld without leakage;

Meet all above mentioned conditions is qualified.

3.Water Tank Usage, repair and maintenance:

When match the pipe, please don’t put excessive pressure on both inlet and outlet of the pipe;

Don’t put the weight of valve and large diameter pipe on the tank outlet. If necessary, please set pipe support or lifting support;

For the expansion, contraction and vibration the welded pipe , ,please must install stretched flexible connectors;

4.Water tank allocation and accessories:

The supplying scope of our water tank mainly includes: cabinet, maintenance hole with lock, ladder, short pipe and single flange.

Our company can also provide matching accessories according to customer’s requirement, such as floating ball valve, glass tube level gauge and all kinds of water tank disinfection equipment and so on.

Water tank Usage, Repair and Maintenance:

1.When connect the pipe, please don’t put excessive pressure on both inlet and outlet of the pipe;

2. Don’t put the weight of valve and large diameter pipe on the tank outlet. When connect, please set pipe support or lifting support;

3. When the welded pipe expand, contract and vibrate, ,please must install stretched flexible connectors;

4.Water tank allocation and accessories:

cabinet, HDG U-steel base, organic glass tube level gauge, maintenance hole with lock, ladders for both inner and outer of the cabinet, short pipe and flange for cabinet.